Musashi is working on the transformation of manufacturing leading a new era.

To grasp a chance to expand new markets resulting from Industry 4.0, we bring a smart factory into reality. Tools & Machinery provides a new answer to every need in manufacturing on the floor by utilizing our "weapon" of the accumulated technology of fabricating unique equipment, prototypes, jigs, dies and cutting tools.

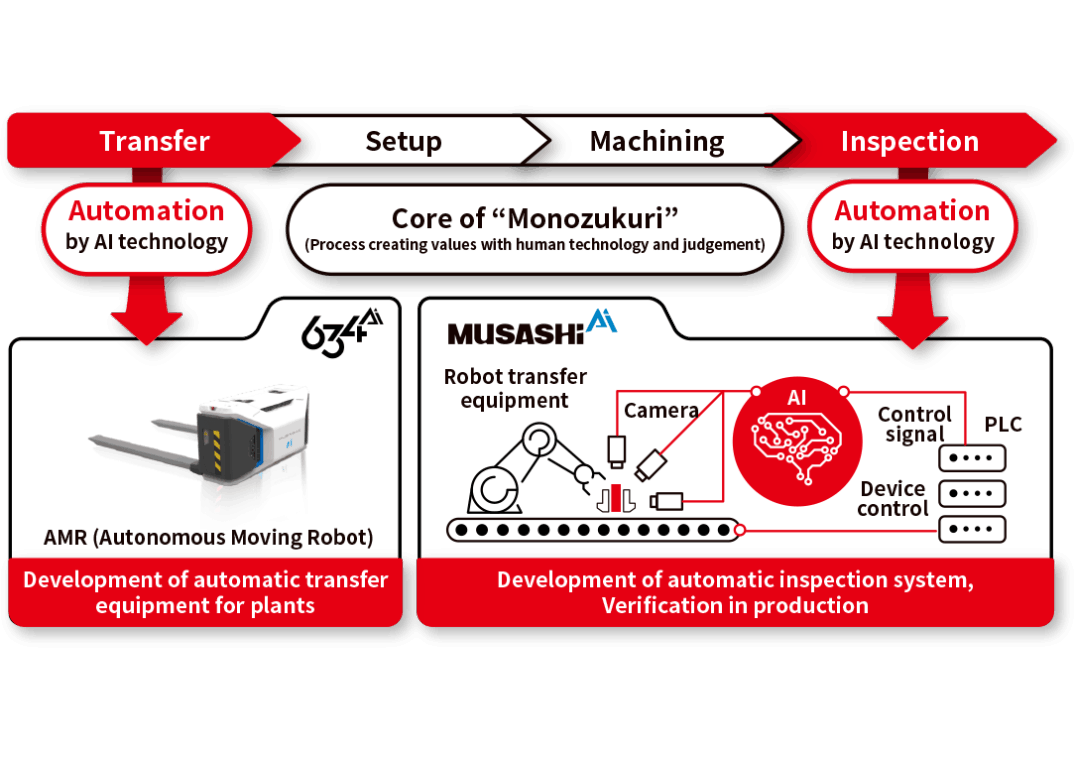

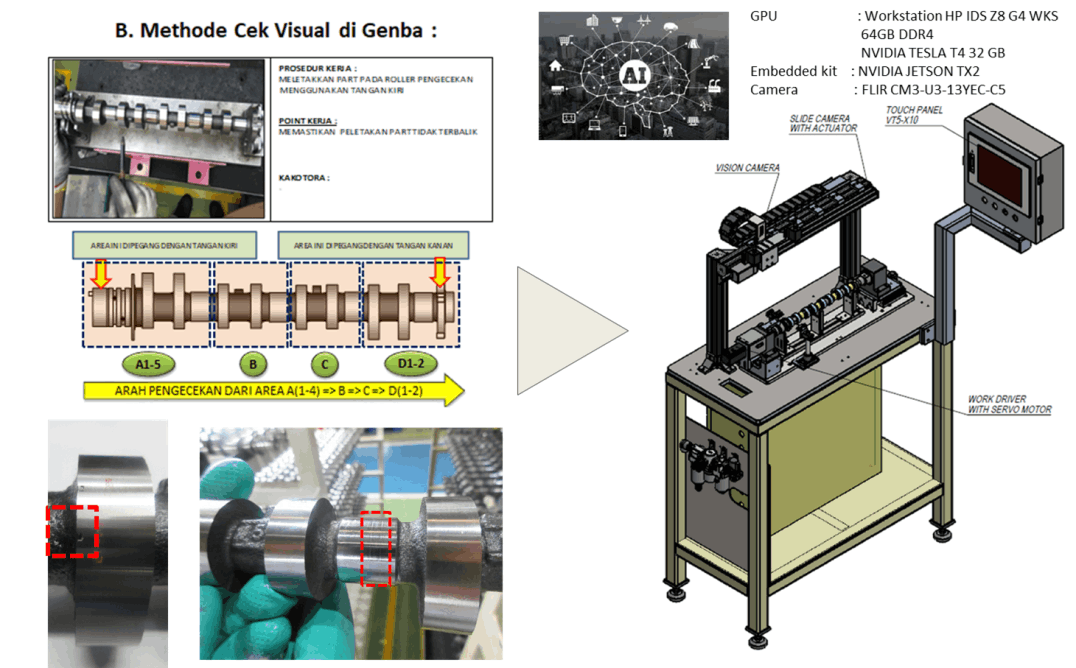

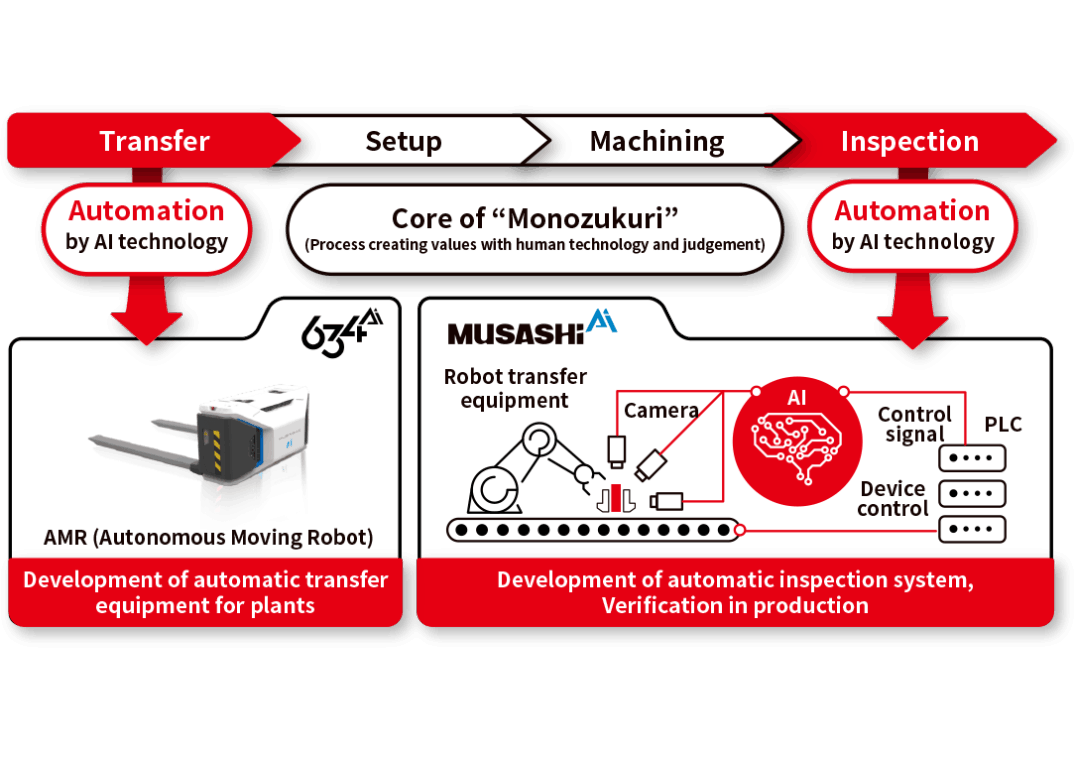

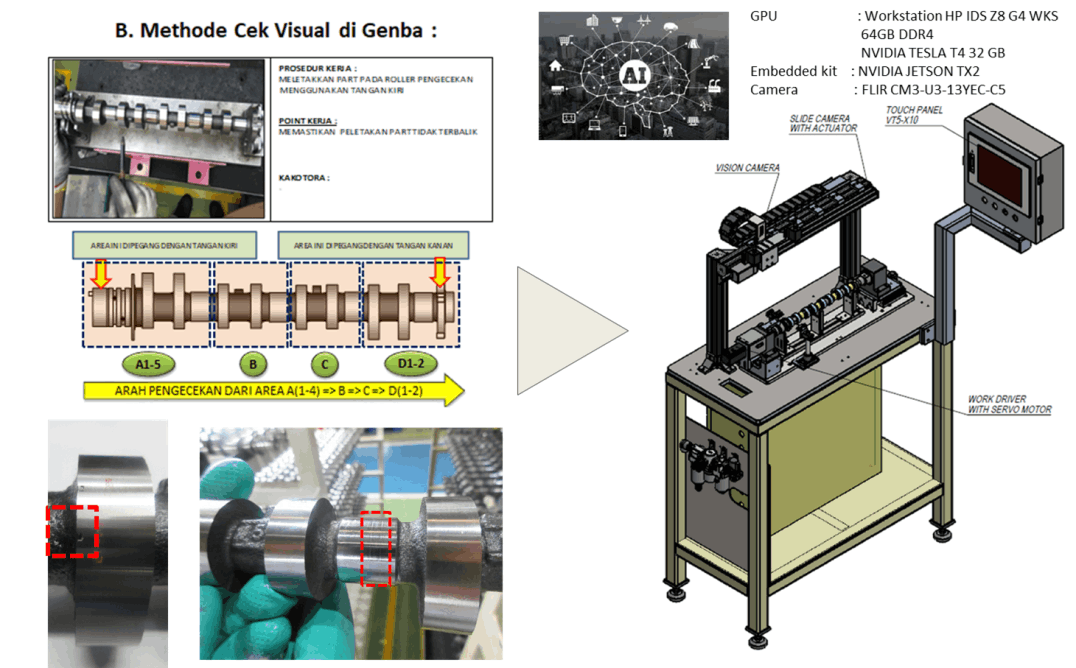

Manual transfer or visual inspection is a long-hour routine process requiring high load in production. Under the slogan "human jobs for humans", Musashi AI is working on Monozukuri innovation by implementing AI in production to release people from high-load routine work.

Based with our "human jobs for humans", we are innovating manufacturing by integrating AI into production processes.

Our products are delivered to customers through the process of transfer, machining, and inspection. Machining is a core of "Monozukuri" that values are added by human technology and judgment. The process of transfer and visual inspection, on the other hand, is a long-hour and high-load routine work.

Human beings, however, are naturally creative. By automating repetitive tasks, we can enable people to focus on innovation and continue developing their work. We are committed to creating an environment that allows individuals to engage in meaningful and creative roles. We aim to keep providing our group plants as well as global manufacturers with a wide range of technologies.